The 4L60E transmission, a reliable GM automatic overdrive unit, is widely used in rear-wheel-drive vehicles․ Its diagram PDF offers detailed insights into components and functionality․

1․1․ Overview of the 4L60E Transmission

The 4L60E is a widely used electronic automatic overdrive transmission designed for rear-wheel-drive vehicles․ It is a successor to the THM 700-R4, offering improved performance and efficiency․ Known for its durability, it is commonly found in GM trucks and SUVs․ A 4L60E transmission diagram PDF provides detailed schematics, making it easier to understand its components and inner workings․ This resource is invaluable for technicians and DIY enthusiasts aiming to repair or rebuild the transmission effectively․

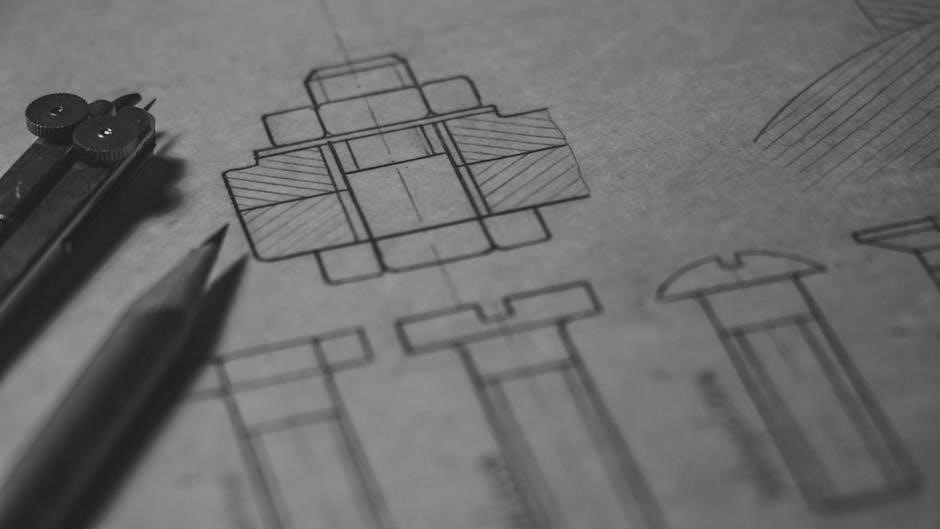

1․2․ Importance of the Transmission Diagram

A 4L60E transmission diagram PDF is essential for understanding the internal workings of the transmission․ It provides a visual guide to components, connections, and their functions, aiding in diagnostics and repairs․ The diagram helps identify potential issues, such as faulty solenoids or worn clutch packs․ It also guides proper assembly during rebuilds, ensuring all parts are correctly installed․ For technicians and DIY enthusiasts, this resource is crucial for maintaining and repairing the 4L60E effectively and efficiently․

Key Components of the 4L60E Transmission

The 4L60E transmission includes a pump body, torque converter, planetary gears, clutch packs, and solenoids․ These components work together to facilitate smooth gear transitions and power delivery․

2․1․ Major Parts of the 4L60E Transmission

The 4L60E transmission comprises several critical components, including the pump body, which generates hydraulic pressure, and the pump cover, ensuring proper fluid circulation․ The torque converter facilitates smooth power transfer, while the planetary gear sets enable gear ratio changes․ Additionally, clutch packs and band assemblies manage torque application, and solenoids control automatic shifting․ These parts, detailed in the 4L60E transmission diagram PDF, are essential for optimal performance and reliability․

2․2․ Hydraulic System Components

The 4L60E transmission’s hydraulic system includes a pump that generates fluid pressure, a valve body to control fluid flow, and solenoids for electronic shifting․ The pressure regulator ensures proper pressure levels, while hydraulic accumulators smooth gear changes․ Additional components like fluid passages and seals maintain system integrity․ These parts, detailed in the 4L60E transmission diagram PDF, are vital for efficient operation and precise control of the transmission’s hydraulic functions․

Understanding the Hydraulic System

The 4L60E’s hydraulic system uses pressurized fluid to engage gears and control shifts․ The pump generates pressure, while solenoids and valves direct fluid flow, as shown in the PDF diagram․

3․1; Hydraulic System Overview

The 4L60E’s hydraulic system regulates fluid pressure to control gear shifts and torque transfer․ It consists of a pump, solenoids, and valves that direct fluid flow․ The pump generates pressure, while solenoids and valves manage the flow to engage clutches and bands․ This system is critical for smooth operation and is detailed in the 4L60E transmission diagram PDF, which illustrates components like the pump body, case, and valve assembly, helping technicians understand hydraulic circuits and diagnostics․

3․2․ Pump Body and Pump Cover

The pump body and pump cover are key components in the 4L60E’s hydraulic system․ The pump body houses the gear set that generates fluid pressure, while the pump cover contains the pressure regulator; Together, they ensure consistent pressure supply for smooth gear shifts․ The 4L60E transmission diagram PDF provides detailed schematics of these parts, aiding in disassembly, inspection, and repair․ Proper alignment and sealing are crucial to prevent leaks and maintain optimal performance․

Transmission Repair and Maintenance

Regular maintenance is crucial for the 4L60E’s longevity․ Inspect and replace worn components, such as gaskets and seals, to prevent leaks and ensure smooth operation․

4․1․ Disassembly and Reassembly Steps

Disassembling the 4L60E transmission requires careful planning and tools․ Start by removing the torque converter and pump, followed by the planetary gearset․ Use a diagram to guide the process․ Clean all components thoroughly to ensure proper reassembly․ Reassemble in reverse order, ensuring all gaskets and seals are replaced․ Proper alignment and torque specifications are critical for functionality․ Always reference a technical manual for precise steps and safety precautions․

4․2․ Transmission Fluid Capacity and Change

The 4L60E transmission typically holds approximately 4․5 to 5 quarts of ATF (Automatic Transmission Fluid)․ Use Dexron VI for optimal performance․ To change the fluid, drain the pan, replace the filter, and refill with fresh fluid․ Ensure the vehicle is on level ground for accurate fluid level checks․ Refer to a transmission diagram for precise locations of the drain plug and fluid pan․ Regular fluid changes are crucial for maintaining smooth gear engagement and preventing overheating․

4L60E Transmission Rebuild Guide

The 4L60E rebuild guide provides step-by-step instructions for disassembling, inspecting, and reassembling the transmission․ Use a transmission diagram for clarity on component locations and torque specifications․

5․1․ Rebuild Tips and Tricks

For a successful 4L60E rebuild, use a transmission diagram PDF to identify components accurately․ Essential tools like a torque wrench and bearing puller are required․ Refer to the technical manual for specific part numbers and torque specifications․ Inspect all components for wear and replace seals and gaskets․ Ensure the pump body and cover are aligned properly․ Clean all parts thoroughly before reassembly to prevent contamination․ Follow step-by-step instructions to avoid costly mistakes and ensure optimal performance post-rebuild․

5․2․ Tools and Equipment Required

To rebuild the 4L60E transmission, essential tools include a torque wrench, bearing puller, and press․ A dial indicator and seal installer are also crucial․ Use a transmission diagram PDF to identify components and their locations․ Common tools like screwdrivers, wrenches, and punches are necessary․ Specialized tools, such as a transmission pan gasket scraper, ensure proper disassembly and reassembly․ Refer to the PDF for a detailed parts list to ensure no tools are overlooked during the process․

Troubleshooting Common Issues

The 4L60E transmission diagram PDF helps identify common issues like slipping, erratic shifts, or solenoid faults․ Use it to trace problems and apply targeted solutions effectively․

6․1․ Common Problems with the 4L60E

The 4L60E transmission often experiences issues like slipping, erratic shifting, and torque converter malfunctions․ Worn clutch packs, faulty solenoids, and low fluid levels are frequent culprits․ 4L60E transmission diagram PDF aids in diagnosing these problems by illustrating component locations and hydraulic circuits․ Slipping between gears and delayed engagements are also common, often linked to internal wear or fluid contamination․ Regular maintenance and reference to the PDF can help identify and address these issues before they escalate․

6․2․ Diagnostic Steps and Solutions

Diagnosing 4L60E issues begins with scanning for error codes and inspecting fluid condition․ Transmission diagram PDF guides visual checks of components like solenoids and sensors․ Pressure testing hydraulic circuits and verifying solenoid operation are crucial steps․ Replacing faulty parts, such as the TCC solenoid or torque converter, often resolves problems․ Proper fluid levels and clean filters are essential․ Consulting repair manuals and diagrams ensures accurate troubleshooting and effective solutions for common transmission issues․

Transmission Diagrams and Schematics

The 4L60E transmission diagram PDF provides detailed schematics, including component layouts, hydraulic circuits, and wiring harnesses․ It covers early and late-style output shafts, solenoid connections, and valve body configurations for precise repairs and rebuilds․

7․1․ Detailed Component Diagrams

The 4L60E transmission diagram PDF includes detailed illustrations of all components, such as the pump, torque converter, valve body, and clutch packs․ These diagrams provide a clear view of hydraulic circuits, solenoid connections, and gear engagement mechanisms․ They also highlight the layout of the output shaft, input shaft, and planetary gear sets․ Compatibility with models like 4L60, 4L65E, and 4L70E is noted, making it a comprehensive resource for repairs and rebuilds․

7․2․ Wiring Harness and Solenoid Diagrams

The 4L60E transmission diagram PDF includes detailed wiring harness and solenoid diagrams, essential for understanding electrical connections․ These diagrams show the TCC solenoid, wiring harness layout, and solenoid pack connections․ They also illustrate how the transmission control module interacts with the solenoids and sensors․ Compatibility with models like 4L65E and 4L70E is noted, making it a valuable resource for diagnosing and repairing electrical issues in GM automatic transmissions․

Torque Converter and TCC Solenoid

The torque converter in the 4L60E transmission is crucial for smooth power transfer․ The TCC solenoid controls lock-up functionality, improving fuel efficiency․ Detailed diagrams in the PDF guide installation and troubleshooting, ensuring proper electrical connections and compatibility with late-model transmissions․

8․1․ Torque Converter Removal and Installation

Removing and installing the torque converter on a 4L60E transmission requires careful attention to detail․ The process involves disconnecting the transmission cooler lines, removing the torque converter bolts, and carefully sliding the converter off the input shaft․ Proper alignment during installation is critical to ensure smooth engagement․ Referencing the 4L60E transmission diagram PDF provides visual guidance for accurate placement and reconnection of components, ensuring optimal performance and preventing potential damage to the transmission system․

8․2․ TCC Solenoid Replacement

Replacing the TCC (Torque Converter Clutch) solenoid in a 4L60E transmission involves removing the solenoid and wiring harness․ Disconnect the electrical connector and remove the retaining clips․ Gently pull the solenoid from its mounting position․ Install the new solenoid, ensuring proper alignment and secure fastening․ Reconnect the wiring harness and test the system․ Referencing the 4L60E transmission diagram PDF ensures accurate placement and connections, preventing issues like slipping or poor engagement․

Output Shaft and Compatibility

The 4L60E transmission features early-style (large) and late-style (small) output shafts, ensuring compatibility with various GM models․ The 4L60E transmission diagram PDF aids in identifying proper configurations․

9․1․ Early-Style vs․ Late-Style Output Shafts

The 4L60E transmission features two distinct output shaft styles: early-style (large spline) and late-style (small spline)․ The early-style shaft is commonly found in older GM vehicles, while the late-style shaft was introduced for compatibility with newer models․ Both designs ensure proper fitment across various applications, but swapping them requires careful consideration of vehicle specifications․ The 4L60E transmission diagram PDF provides clear visuals to identify and distinguish these shafts, aiding in accurate installations and upgrades for enthusiasts and mechanics alike․

9․2․ Compatibility with Other Transmission Models

The 4L60E transmission is compatible with several GM models, including the 4L60, 700-R4, 4L65E, 4L70E, 4L80E, and 4L85E․ While these transmissions share similarities, specific components like output shafts and solenoids may differ․ The 4L60E transmission diagram PDF helps identify compatible parts and configurations, ensuring proper installation and functionality when swapping or upgrading transmissions․ Adapters and conversion kits are often required for seamless integration across different models, making the 4L60E versatile for various applications․

4L60E Transmission PDF Resources

Various 4L60E transmission diagram PDF resources are available, including technical manuals like ATSG (4726․74400EA) and part number guides for 4L60, 700-R4, and other models․

10․1․ Technical Manuals and Repair Guides

Technical manuals and repair guides for the 4L60E transmission are essential resources, offering detailed instructions for troubleshooting, disassembly, and reassembly․ The ATSG (Automatic Transmission Service Group) manual (document number 4726․74400EA) is a comprehensive guide, providing part numbers, diagrams, and repair procedures․ These resources are invaluable for both professionals and DIY enthusiasts, ensuring accurate and efficient transmission service․ They cover various models, including the 4L60, 700-R4, 4L65E, and 4L70E․

10․2․ Free Downloadable PDF Files

Free downloadable PDF files for the 4L60E transmission are widely available, offering detailed diagrams, repair guides, and technical manuals․ The ATSG (Automatic Transmission Service Group) manual (document number 4726․74400EA) is a popular resource, providing comprehensive instructions and part numbers․ Additionally, transmission diagrams and user manuals can be found online, aiding in troubleshooting and maintenance․ These PDFs are invaluable for DIY enthusiasts and professionals alike, ensuring easy access to essential information․

Transmission Parts and Kits

Transmission part kits for the 4L60E include component-specific sets for repair and maintenance․ These kits cover bearings, gaskets, seals, and clutch packs, ensuring compatibility and durability․

11․1․ Transmission Part Numbers and Kits

Transmission part numbers for the 4L60E vary based on specific components, such as bearings, gaskets, and seals․ Kits are available for complete overhauls or targeted repairs, ensuring compatibility․

These kits often include detailed part lists and diagrams, making it easier to identify and source the correct components for your transmission rebuild or maintenance project․

11․2․ Where to Find Genuine Parts

Genuine 4L60E parts can be sourced from authorized GM dealerships, ensuring authenticity and quality․ Online retailers like RockAuto and transmission specialty shops also offer a wide range of components․

Additionally, repair manuals and PDF diagrams provide part numbers, making it easier to locate the exact components needed for your transmission repair or rebuild project․

Safety Tips for Transmission Work

Safety is crucial when working on the 4L60E transmission․ Always wear protective gear, ensure proper ventilation, and use jack stands for support․ Handle transmission fluid carefully and follow torque specifications to avoid injuries and damage․

12․1․ Essential Safety Precautions

When working on the 4L60E transmission, always wear protective gear, including gloves and safety glasses․ Ensure the vehicle is securely supported with jack stands to prevent accidents․ Use proper tools designed for transmission work to avoid damage or injury․ Handle transmission fluid carefully, as it can be slippery and harmful if ingested․ Always follow torque specifications and avoid over-tightening components․ Keep the workspace clean and well-lit to minimize risks․ Never work on a hot transmission; allow it to cool first․ Proper ventilation is crucial when dealing with fluids and chemicals․

12․2․ Protective Gear and Tools

Essential protective gear includes gloves, safety glasses, and a face mask to prevent injury from debris and fluids․ A socket set, torque wrench, and drain pan are vital tools for handling transmission components․ Use a hydraulic press for bearing removal and a seal installer to prevent damage․ Keep a clean work area with rags and a parts organizer․ A transmission jack or sturdy table is necessary for safe handling․ Always refer to the 4L60E diagram for specific tool requirements․

DIY vs․ Professional Repair

A transmission diagram PDF aids both DIY enthusiasts and professionals․ DIY repair suits knowledgeable individuals, while complex issues often require professional expertise for reliable outcomes․

13․1․ When to Choose DIY Repair

DIY repair is ideal for minor issues like fluid changes or filter replacements, where mechanical skills and tools are sufficient․ Access to a transmission diagram PDF and repair manuals can guide the process, making it easier for knowledgeable individuals to handle simple fixes confidently․ However, complex problems requiring specialized tools or expertise should be left to professionals to ensure safety and reliability․

13․2․ When to Consult a Professional

Consult a professional for complex issues like clutch pack replacements or solenoid malfunctions, which require specialized tools and expertise․ Transmission diagrams and schematics can help professionals diagnose and fix issues efficiently․ They ensure proper reassembly and fluid installation, preventing further damage․ DIY attempts in such cases may lead to costly errors, making professional intervention the safer and more reliable option for long-term performance and durability․

Common Upgrades for the 4L60E

Popular upgrades include high-performance clutch packs, reinforced gear sets, and improved cooling systems․ These enhancements boost durability and performance, especially for heavy-duty or high-torque applications․

14․1․ Performance Upgrades

Performance upgrades for the 4L60E include high-stall torque converters and billet input shafts․ These modifications enhance power delivery and durability, making them ideal for racing or towing applications․ Additionally, installing a performance clutch pack improves heat resistance and friction, ensuring smoother shifts under stress․ Upgraded valvebody components can also be added to refine shift patterns and increase transmission responsiveness․ These upgrades are detailed in various transmission diagrams and PDF guides, which provide step-by-step installation instructions․ Proper installation of these components requires precise tools and technical expertise, as outlined in specialized repair manuals․ Regular maintenance and fluid changes are essential to maintain the longevity of these upgrades․ By following the guidelines from these resources, enthusiasts can significantly enhance their transmission’s performance and reliability․ Whether for daily driving or extreme conditions, these upgrades ensure the 4L60E operates at its peak efficiency․

14․2․ Durability Enhancements

Durability enhancements for the 4L60E include reinforced components like high-performance gaskets and seals to prevent leaks․ Upgraded planetary gear sets and input shafts improve strength under heavy loads․ Applying heavy-duty coatings to bearings and gears extends lifespan․ Enhanced valvebody components ensure consistent pressure control, reducing wear․ These modifications are detailed in transmission diagrams and PDF guides, offering clear installation steps․ They are ideal for vehicles used in demanding conditions, ensuring long-term reliability and performance․ Regular inspections and maintenance further complement these upgrades for optimal durability․

The 4L60E transmission is renowned for its reliability and versatility․ Utilizing detailed diagrams and adhering to proper maintenance schedules ensures optimal longevity and performance․ Regular updates enhance its durability and dependability․

15․1․ Final Thoughts on the 4L60E Transmission

The 4L60E transmission is a testament to GM’s engineering excellence, offering reliability and versatility across various vehicle applications․ Its widespread use in rear-wheel-drive models underscores its durability․ The availability of detailed diagrams, repair manuals, and rebuild guides empowers enthusiasts and technicians alike․ Whether for routine maintenance or complex overhauls, the 4L60E remains a preferred choice․ Proper care and adherence to technical specifications ensure its longevity, making it a cornerstone of automotive performance and dependability․

15․2․ Importance of Proper Maintenance

Regular maintenance is crucial for the 4L60E transmission’s longevity․ Fluid changes, filter replacements, and inspections prevent premature wear․ Using a 4L60E transmission diagram PDF ensures accurate repairs․ Proper care avoids costly breakdowns and ensures smooth performance․ Adhering to maintenance schedules extends the transmission’s lifespan, making it a reliable choice for drivers․ Neglecting upkeep can lead to severe damage, emphasizing the need for consistent attention to this essential automotive component․

Further Reading and References

For in-depth knowledge, refer to technical manuals and repair guides like the ATSG 4L60E Update․ Explore free downloadable PDF files and online forums for detailed insights and troubleshooting tips․ These resources provide comprehensive information on transmission diagrams, maintenance, and upgrades, ensuring a thorough understanding of the 4L60E transmission system․

16․1․ Recommended Books and Manuals

For comprehensive guidance, the ATSG 4L60E Technical Manual (part #4L60E-UPDATE) is highly recommended․ It provides detailed repair procedures and diagrams․ Additionally, the 4L60E Transmission Rebuild Manual offers step-by-step instructions for rebuilding and maintaining the transmission․ These resources, along with Automatic Transmission Repair Manuals, cover essential topics like hydraulic systems, torque converters, and troubleshooting․ They are invaluable for both professionals and DIY enthusiasts seeking to understand and work on the 4L60E transmission effectively․

16․2․ Online Resources and Forums

Online platforms like GitHub offer valuable resources, including diagrams and repair guides for the 4L60E transmission․ Websites dedicated to transmission repair provide detailed PDFs, such as the 4L60E Transmission Diagram PDF and ATSG 4L60E Technical Manual․ Additionally, forums and communities like transmission rebuild groups share insights, troubleshooting tips, and real-world experiences․ These resources are essential for enthusiasts and professionals seeking to understand and work on the 4L60E transmission effectively․